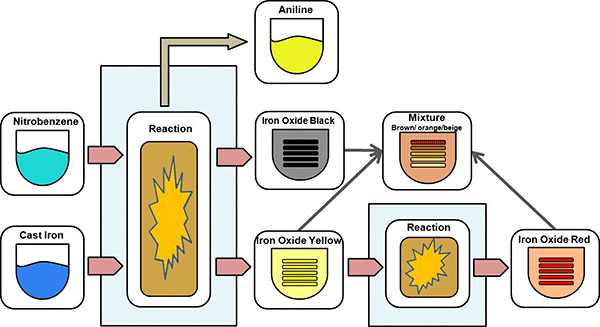

Iron oxide pigments mainly refer to iron oxide red, iron black, iron yellow, iron brown, iron orange yellow, transparent iron oxide and other coloring pigments of iron oxide oxides whose basic substance is iron oxide.

Traditionally used as mica iron oxide to prevent rust, as heat-resistant ferrate pigments and magnetic iron oxide used as magnetic recording materials also belong to the category of iron oxide pigments. Iron oxide pigment is widely used in coating, building materials, plastics, electronics, tobacco, optical glass polishing agent, medicine, advanced fine grinding materials, pet feed additives and other industries due to its many colors, chromatography, non-toxicity and low price.

More than 80% of the iron oxide pigments consumed in the world are synthesized by chemical methods, known as synthetic iron oxide. Because the particles are neatly hooked, good hue, excellent application performance and other characteristics, synthetic iron oxide pigment has been widely used. In recent years,China’s iron oxide pigment industry is developing rapidly, there are more than 80 manufacturers, the production capacity of about 320,000 t/a, the output accounts for about 1/3 of the world’s total output, the export volume has exceeded 50% of the total annual output, making China the second largest iron oxide pigment exporter after Germany, remarkable economic benefits.

The development of iron oxide pigment is worth some problems:

1. At present, the domestic production of iron oxide pigments, a few varieties, lack of characteristics, such as export iron oxide red is only the color of the points facing the international market challenges, if the product quality is still at a low level, there is no new characteristics, at any time may be eliminated by the surrounding countries (such as India) in the competition.

2. At present a large part of synthetic iron in our country is made of tin. If enterprises only stay in the pursuit of production scale and ignore the development of resources, it is bound to cause the exhaustion of limited iron resources. Therefore, it is urgent to open up new ways of raw materials.

3. New iron oxide pigments to be developed At present, most of the iron oxide pigments produced in China are universal and untreated pigments. This kind of universal iron oxide has low price and low added value. Therefore, it is necessary to develop new pigments of iron oxide series.

The following kinds of iron oxide pigments should be developed:

1. Micro-ferric oxide

The synthetic ferric oxide is crushed to micron or even nanometer size with ultrafine grinding equipment, known as ultrafine ferric oxide. Ultrafine iron oxide can improve the coloring power, and easy to disperse, high film luster, and can prevent sinking, floating color, hair in the application system, therefore, ultrafine iron oxide has a good application prospect. The key technologies are to use surfactants to solve the problem of particle agglomeration and to develop high efficiency and energy saving pulverizing equipment.

2. Heat-resistant grade iron oxide

General iron oxide yellow, iron oxide black in containing crystalline water, at 177 ℃ began to dehydrate or oxidation discoloration. Therefore, it can not be used in plastics and baking coatings that need to be processed at higher temperatures. After nuclear treatment, can improve the heat resistance, suitable for polypropylene, auto maintenance paint, coil paint, all kinds of color paste and high gloss latex paint.

3. Low oil absorption and high dispersion iron oxide

In order to facilitate the use of modern inorganic pigments also began to consider the manufacture of high concentration of color paste, which requires the pigment to have a lower oil absorption and good dispersion. By adding surface treatment agents and mechanical crushing, particle shape can be changed, oil absorption reduced and dispersion improved.

In recent years, although Chinese synthetic iron pigment industry has made great progress, but compared with the developed countries, there is an obvious gap, mainly lies in backward technology, single variety and raw materials, small scale enterprise, poor efficiency. Therefore, it is urgent for the development of iron oxide pigment industry to improve product quality, increase product variety and expand raw material source.

Post time: Jan-05-2023