Carbon Black Pigment N220 N330 N550 Used As Chemical Auxiliary Agent

Product Introduction

Carbon Black is an additive mainly used for coloring and rubber and plastic products reinforcement. The feature that made Carbon Black widespread in the industrial production is its ability to give a deep, everlasting black color.

Carbon black contains more than 99% pure carbon. Other components are oxygen, hydrogen, and nitrogen. It is available in powder or beads (pellet) form. The black particles are 10nm to approximately 100nm in size and fuse into chain-like aggregates, which define the structure of individual Carbon Black grades. Depending on the production process parameters, Carbon Black types differ in particle size, structure, surface chemistry, porosity, and many other characteristics. The properties of most Carbon Black grades are determined by industry-wide standards. The American Society for Testing and Materials (ASTM) is the most widely used, especially for Rubber Carbon Black grades.

Carbon Black is a fine black powder made by the controlled incomplete combustion or thermal decomposition of hydrocarbons. Known for its exceptional blackness, high surface area, and reinforcing properties, it is widely used across coatings, rubber, plastics, and ink industries. XT Pigment provides a range of carbon black grades designed for both color and performance applications.

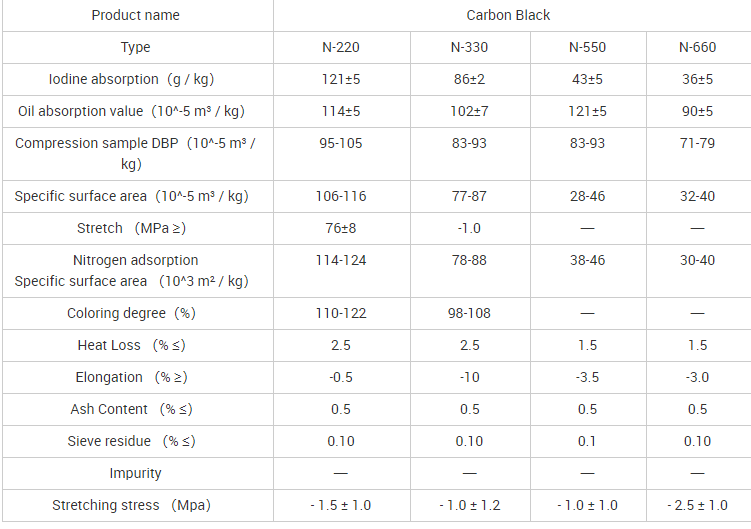

Shade Card (Technical Data)

Feature

-

Deep Jet Black Appearance

Provides intense color depth for formulations where darkness and coverage are essential. -

High Surface Area (BET)

Contributes to UV resistance and mechanical reinforcement, especially in elastomers and industrial coatings. -

Conductive & Antistatic Grades Available

Used in electronics packaging, battery electrodes, and ESD-safe plastics. -

Excellent Dispersibility

Tailored particle size distribution ensures fast and stable dispersion in water- and solvent-based systems. -

Thermal & Chemical Stability

Withstands extreme conditions without degradation, suitable for demanding industrial use.

Main Uses

Carbon black is used in various formulations with different rubber types to customize the performance properties of tires. Engineers combine different tread and carcass grades of carbon black to optimize such properties as handling, treadwear, fuel mileage, hysteresis and abrasion resistance for the ever changing needs of today’s drivers.

Carbon black can be used in tire and rubber products reinforcement, It is pure black powder or ganular, and has high reinforcement capacity for rubber products and tire manufacture, and could increase rubber service life. Our company could custome produce carbon black products depend on customers requirement.

Industry Carbon Black N220

Applicatons: paints, plastics, inks, coatings & more

Carbon Black N330

Good wear properties and processing. Used in passenger through truck tires.

Carbon Black N550

It is primarily used in steel wire-coat compounds for radial tires.

Carbon Black N660

Industry standard carcass / innerliner compound black.

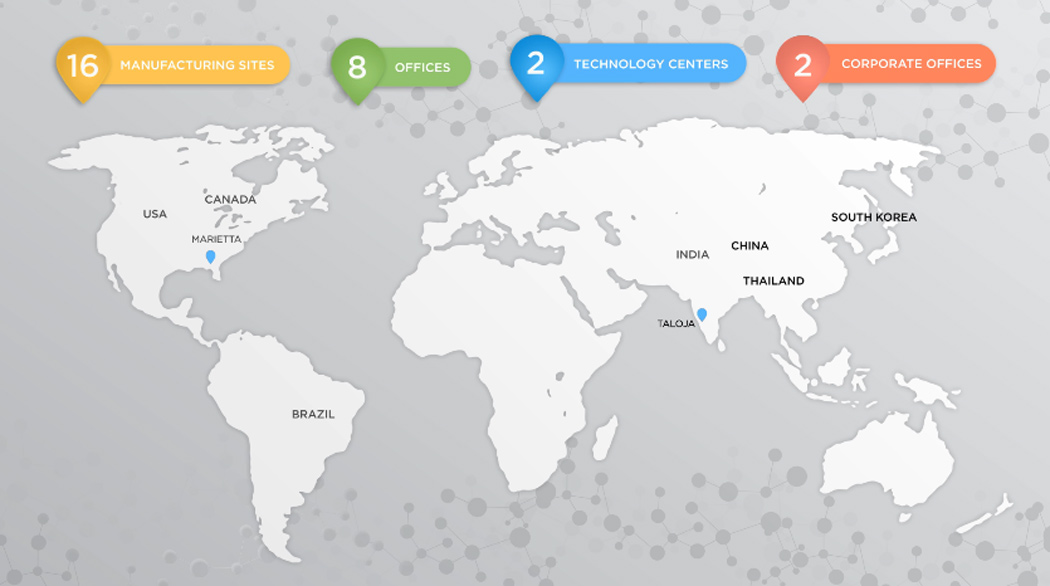

Global Capabilities, Global Solutions

We delivers effective solutions anywhere and anytime you need to help you succeed.